how do compression fitting work

The nut is fitted into a ring-like structure. How Does it Work A compression valve actually looks like a valve as you would understand it.

Reliability Of Plumbing Fittings Threaded Vs Compression Ctg Technical Blog

Ad Compliant Safety Since 1906.

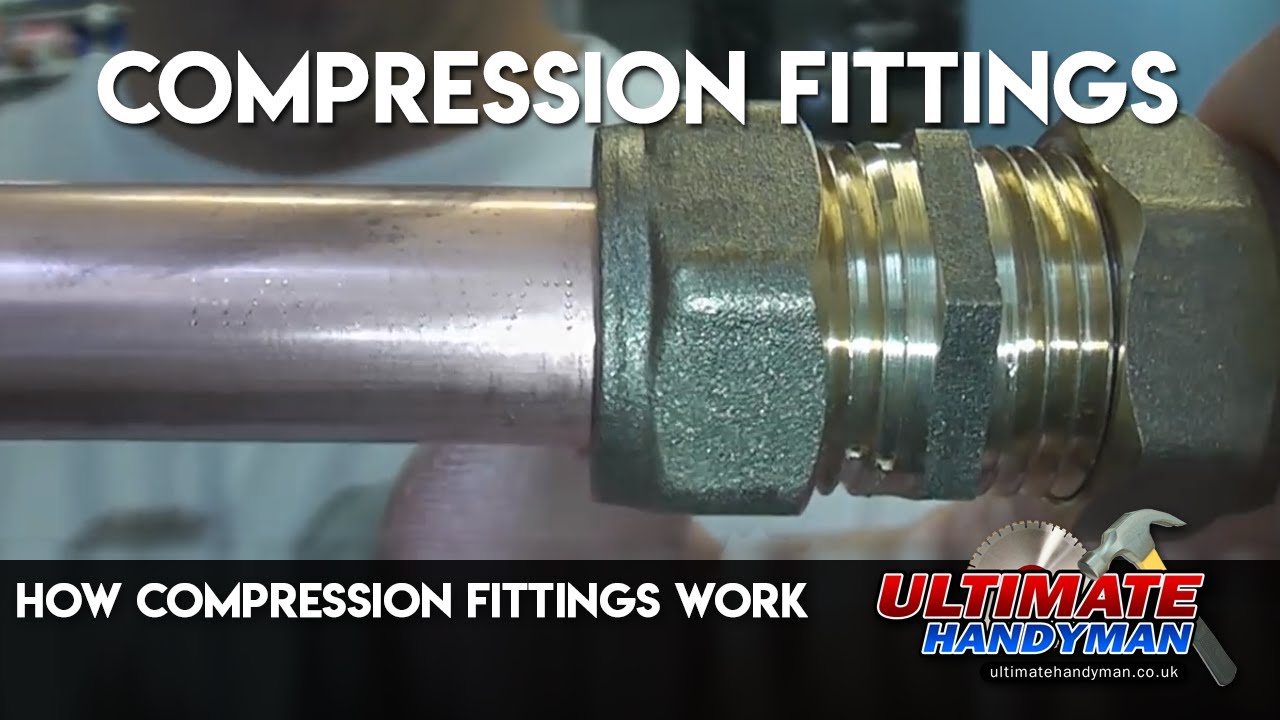

. Compression fittings are very versatile but many people are not confident when using them. Compression fittings are one of the most common and versatile methods of. How does compression fitting work.

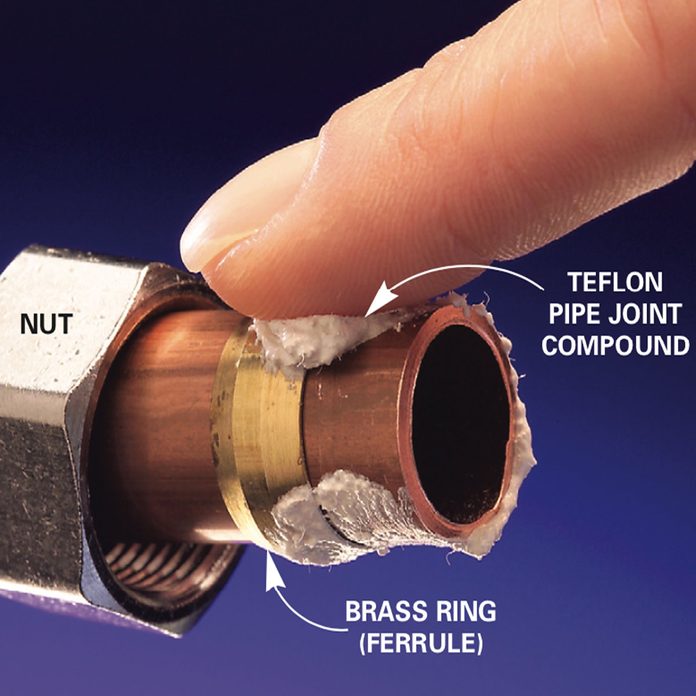

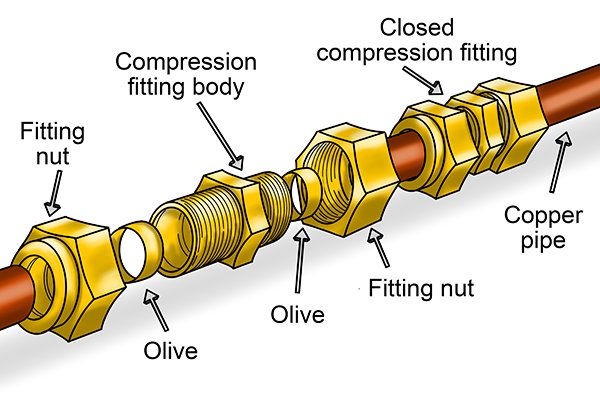

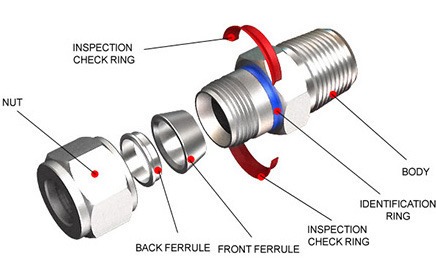

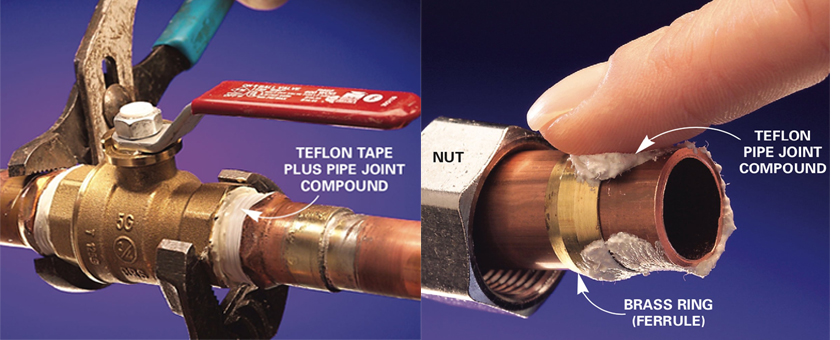

The ferrule is the primary sealing component of a compression fitting assembly and they can be found in a. Some people also believe that you need to use a sealing compound. Compression fittings work by the compression of an olive between two tapered surfaces and the pipe itself.

A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. If the Tubing Kinks. It has a copper wedding-style compression ring which fits inside the valve.

Tighten the cutter so the cutting wheel is snug against the pipe. In addition metal compression fittings are generally easier to disinfect and clean than other materials. In this video I show you how compression fittings work.

Thus when a compression fitting is installed the nut is tightened from one side. This exerts pressure on the olive and bites it onto the pipe. While these fittings may require more work than quick-.

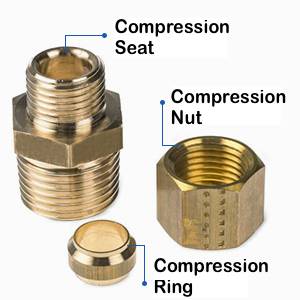

On one side the pipe that is being fitted is slid into a nut-like structure. A compression fitting is a type of coupling used to connect two pipes or a pipe to a fixture or valve. Compression fittings have three main parts.

Using a spanner and a pair of grips the nut is tightened. Ad Shop Zoro to Get Fast Free Shipping on Orders of 50 and Hassle-Free Returns. Position the Parts and Join Them.

Cut the Pipe Cut the end of the pipe if necessary using a tubing cutter. The Basics of Compression Fittings Introduction to Compression Fittings. A brief video about how PVC compression fittings work.

Software engineers have always developed new ways of fitting a lot of data into a small space. Compression fittings work by the compression of an olive between two tapered surfaces and the pipe. Compression fittings for attaching tubing commonly have ferrules in them.

Click to see full answer. The compression fitting has become less popular since the introduction of quick-connect style connections to the water treatment sector but its still a great fitting that can tolerate high pressure and provide a. Also how their tapered rubbe.

Thats why it also has high purity applications. How to Install a Compression Fitting on Copper Pipe Step 1. File compression plays a big part in connecting us letting us send less data down the line so we can have faster downloads and fit more connections onto busy networks.

Shut Off the Water. The two surfaces are the body of the fitting be it a valve connector or any other type and the nut. As the nut is tightened the compression ring is pressed into the seat causing it to compress against the pipe and the compression nut providing a watertight connection.

Plumbers often use wrenches to clamp the nut to the pipe. These parts are attached to each other by first sliding the nut onto the tube or pipe and then connecting the compression ring. This fits between the joints of two pipes which then compress it together to eliminate the chance of leaks in the joint.

A compression fitting compresses one of the fittings components into another component usually tubing to establish a watertight seal between two lines. Compression fittings use a small nut to compress tubing to create a secure seal to a fixture or valve. Including connection to basin waste and the standard compression fitting.

Compression fittings work by compressing Olives between the fitting nut and pipe faces. How to Join a Compression Union. On the other side of the fitting is a seating or receiving end into which the ring is fitted.

Shut Off the Water. Open the jaws of the tubing cutter and fit it onto the pipe so the pipe rests squarely against the two flat rollers of the cutter. In instances where two pipes made of dissimilar materials are to be joined the fittings will be made of one or more compatible materials appropriate for the connection.

It was true when our hard drives were tiny and the advent of the internet has just made it more critical. In general these fittings are made up of three components. Final Thoughts on Compression Fittings.

Choose from Millions of Items and Sign Up for Zmail to Get 10 Off Your First Order. How to Make a Compression Joint. Your 1 Stop Shop For Safety Cabinets Cans Spill Protection.

Thanks to that pressure will be created. Get the Job Done With the Most Dedicated Team Around. The ring the nut and the seat.

How Does a Compression Fitting Work.

Stop Leaks In Plumbing Joints Diy Family Handyman

Reliability Of Plumbing Fittings Threaded Vs Compression Ctg Technical Blog

Is Your Sink S Compression Fitting Leaking Here S What To Do

Compression Fittings Manipulative Compression Fittings Brass Compression Fittings Compression Fittings Suppliers

What Is An Olive Remover Wonkee Donkee Tools

Brass Tube Fittings Manufacturer India Astm B283 Compression Fitting

How Compression Fittings Work Youtube

Double Ferrule Compression Fittings Projectmaterials

How Compression Fittings Work Joining Copper Pipes And Mlcp Blansol Plumbing Youtube

How To Use A Compression Fitting Compression Plumbing Tutorial Plumbing For Beginners Youtube

How To Stop Brass Fittings From Leaking The Indoor Haven

Compression Fittings Manipulative Compression Fittings Brass Compression Fittings Compression Fittings Suppliers

Inside Scoop Comparing Double Ferrule Fittings And Single Ferrule Fittings Superlok Fittings And Valves

7 Common Speedfit Plumbing And Heating Questions Answered

Using Compression Fittings To Install Plumbing Fixtures

Plumbing What Is The Difference Between Swage Fittings And Compression Fittings Home Improvement Stack Exchange